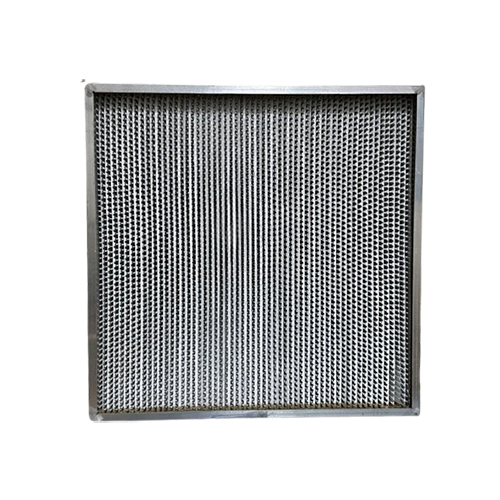

Gas Turbine Air Inlet Filter

Product Details:

Gas Turbine Air Inlet Filter Price And Quantity

- 1 INR/Piece

- 1 Piece

Product Description

Gas Turbine Air Inlet Filters are critical components designed to protect gas turbines from airborne contaminants such as dust, salt, moisture, and industrial pollutants. These filters are engineered to deliver high dust-holding capacity, low pressure drop, and long service life, even in the most challenging environmental conditions (coastal, desert, or industrial areas).

Modern gas turbine filters often utilize mini pleat technology to maximize media area within compact frames. This design ensures efficient filtration, improved airflow, and reduced maintenance intervals, all contributing to better turbine efficiency, reduced fouling, and longer operational uptime.

Gas turbine filters are typically installed in multi-stage filtration systems, with pre-filters, fine filters (F8“F9 or MERV 14“15), and final filters (HEPA or EPA grades) depending on the site environment and performance requirements.

📌 Key Features

-

Filter Types: Panel filters, cylindrical filters, V-bank mini pleat filters

-

Efficiency: EN779: F7“F9 / ISO 16890: ePM1 / EPA/HEPA (E10“H13)

-

Media: Synthetic, fiberglass, or nanofiber media

-

Construction: Galvanized steel or plastic frames; weather-resistant design

-

Pleat Style: Mini pleat for compact design and high media area

-

Optional Features: Hydrophobic coatings, salt barrier layers, anti-static treatment

-

Applications: Gas turbines, compressors, industrial blowers, and large air handling units in power plants, refineries, and offshore platforms

“ FAQs “ Mini Pleat Filters (Gas Turbine Application)

1. Why use mini pleat filters in gas turbines?

Mini pleat filters maximize surface area within a compact frame, offering high airflow, longer service life, and superior particle capture, which are critical in gas turbine efficiency and protection.

2. What contaminants do they protect against?

Gas turbine mini pleat filters capture:

-

Fine dust and PM2.5

-

Oil mist and industrial emissions

-

Salt aerosols (in coastal environments)

-

Moisture and fog particles (when using hydrophobic media)

3. What is the typical service life of mini pleat filters in turbines?

Service life can vary based on environmental conditions but typically ranges from 6 months to 2 years. Sites with high particulate matter or humidity may require more frequent replacement.

4. Can mini pleat filters handle high flow rates?

Yes, mini pleat filters are designed for high-velocity airflow, typically seen in gas turbine inlets, without compromising on filtration efficiency or structural integrity.

5. How do I choose between EPA, HEPA, or F9 filters for turbine use?

-

F7“F9: Used as main filters in most environments

-

EPA (E10“E12): Used in environments with finer particulates or strict turbine protection needs

-

HEPA (H13“H14): Used for extremely clean air requirements, though less common due to higher pressure drop

6. Are mini pleat filters weather-resistant?

Yes, filters used in turbine applications often come with weatherproof construction, UV-resistant materials, and water-repellent coatings for harsh environments.

7. Do mini pleat filters reduce turbine fouling?

Absolutely. By capturing fine and corrosive particles, mini pleat filters prevent compressor fouling, reduce maintenance frequency, and improve turbine output and lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hepa Filter' category

|

M/S ADITYA FILTRATION SYSTEM P LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |