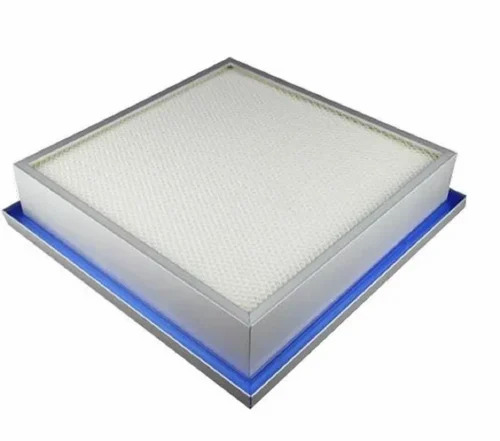

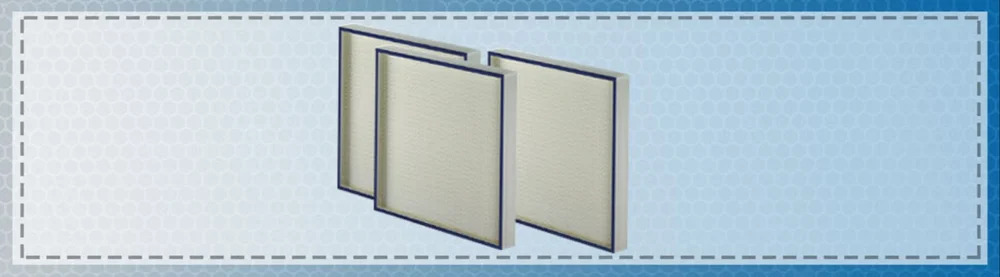

Mini Pleat HEPA/ULPA Filters

Mini Pleat HEPA/ULPA Filters Specification

- Resistance

- Yes

- Usage

- Industrial

- Size

- 4-10 inch

- Material

- Metal

- Product Type

- Mini Pleat Hepa Filter

- Color

- Silver

Mini Pleat HEPA/ULPA Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 5 Days

About Mini Pleat HEPA/ULPA Filters

Mini Pleat HEPA and ULPA Filters are compact, high-efficiency air filters designed for use in critical environments that require superior air cleanliness. Manufactured with ultra-fine glass fiber media arranged in densely packed pleats, these filters offer an extended filtration surface in a reduced footprint, ensuring low pressure drop and longer service life.

They are widely used in cleanrooms, pharmaceutical manufacturing, healthcare facilities, electronics production, and laboratories, where the control of submicron particles is essential. The mini pleat design maximizes filtration area while maintaining a rigid, compact structure, often enclosed in aluminum or ABS plastic frames.

Available in efficiency ratings of H10 to H14 (HEPA) and U15 to U17 (ULPA) per EN 1822 or 99.97% to 99.999995% at 0.3 microns per IEST/ASHRAE standards.

Key Features

-

Efficiency Classes:

-

HEPA: H10H14 (EN 1822) / 99.97%99.995% @ 0.3 m

-

ULPA: U15U17 / Up to 99.999995% @ MPPS

-

-

Media: Microfine glass fiber

-

Frame Material: Aluminum / ABS / Galvanized steel

-

Seal Type: Gasket seal / Gel seal

-

Pleat Style: Mini pleat with hot-melt separators

-

Recommended Final Pressure Drop: 450600 Pa

-

Applications: Cleanrooms, laminar flow units, FFUs, biosafety cabinets, healthcare, semiconductor & optics industries

FAQs Mini Pleat Filters

1. What makes a filter "mini pleat?

Mini pleat filters use tightly packed, narrow pleats with hot-melt spacing to increase the surface area of the media in a compact form. This design reduces pressure drop and extends service life compared to standard pleated filters.

2. How do Mini Pleat HEPA and ULPA filters differ from standard HEPA filters?

The mini pleat version offers higher media area in the same frame size, lower resistance, and better dust-holding capacity. ULPA filters have a higher efficiency than HEPA, capturing smaller particles.

3. What is the difference between HEPA and ULPA filters?

-

HEPA (High Efficiency Particulate Air): Removes 99.97% of particles 0.3 m

-

ULPA (Ultra-Low Penetration Air): Removes 99.9995% of particles 0.12 m

4. Where are mini pleat HEPA/ULPA filters used?

They are used in applications where the highest level of air cleanliness is required, such as:

-

Pharmaceutical cleanrooms

-

Microelectronics manufacturing

-

Hospitals and operation theaters

-

Biosafety cabinets

-

Laminar airflow units and FFUs

5. What are the benefits of mini pleat design?

-

Compact size with high airflow

-

Longer life span

-

Energy savings due to lower pressure drop

-

Stable media structure with no fiber shedding

-

Improved rigidity and integrity

6. Can mini pleat filters be used in variable air volume (VAV) systems?

Yes, due to their rigid construction and uniform airflow characteristics, mini pleat filters are ideal for VAV systems where airflow may fluctuate.

7. How often should Mini Pleat HEPA/ULPA filters be replaced?

Typically every 13 years, depending on:

-

Particle load

-

Environment (cleanroom class)

-

Airflow and pressure drop monitoring

Regular integrity testing (DOP/PAO test) is also recommended.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hepa Filter Category

Gel Seal HEPA Filter

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Resistance : Yes

Size : 410 inch

Usage : Industrial

Microfiber AHU Filter

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Resistance : Yes

Size : 410 inch

Usage : Industrial

HEPA FILTER MINI PLEAT

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Resistance : Yes

Size : 410 inch

Usage : Industrial

H13 HEPA Filter

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Resistance : Yes

Size : 410 inch

Usage : Industrial

|

M/S ADITYA FILTRATION SYSTEM P LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |